Struggling to find a precise and reliable CNC router for your desktop fabrication needs?

In this blog, we showcase the best desktop CNC machines for precision crafting and small-scale manufacturing, from user-friendly models for beginners to high-precision machines for advanced applications, including compact and budget-friendly options.

With over 20 years of experience in precision tools and digital fabrication, we’ve helped countless craftsmen, hobbyists, and small businesses select the right CNC router to bring their creative and engineering projects to life. Our team has personally tested these desktop CNC machines in various applications, ensuring they offer accuracy, efficiency, and adaptability.

Makers have a CNC router in their workshop because it is a classic, essential tool. CNC routers allow you to do a lot of things, including carving wood, cutting materials, and engraving objects. We are looking forward to seeing you!The Best CNC Router: How Do I Choose It?

CNC Routers: What Are They?

Best Home CNC Machine Router 2024

A good place to start is with the BobsCNC E4. An SG20U rail system supports its 610 mm x 610 mm cutting area. You will enjoy working on the laser-cut frame since it is rigid. Compared to the BobsCNC E3, the E4 is very similar to the BobsCNC E3. Stepper motors (Nema 17) power the model E4. Hard plastic or light wood can be worked with this machine. A great package with the best quality of materials is included when you buy it, which is best for just starting out. You can also learn more about Bob’s CNC machine by visiting their YouTube channel.BobsCNC E4 CNC Machine: Best Product Overall

The budget-friendly CNC router from McCwdoit meets all of your needs. The notebook is ideal for desktops that have limited space because of its average size. By simply downloading the necessary files onto the USB key, the necessary files can be accessed offline without a router connected. The offline tool has a storage capacity of 1GB, so multiple projects can be stored. While designed for personal use, this machine is capable of performing tasks without a problem. It’s hard to find a good router out there that will last forever, so this isn’t one of them. The warranty covers this product for a year if it is broken in the first year.Mcwdoit CNC 3018 Pro Router: Best for Desktop Use

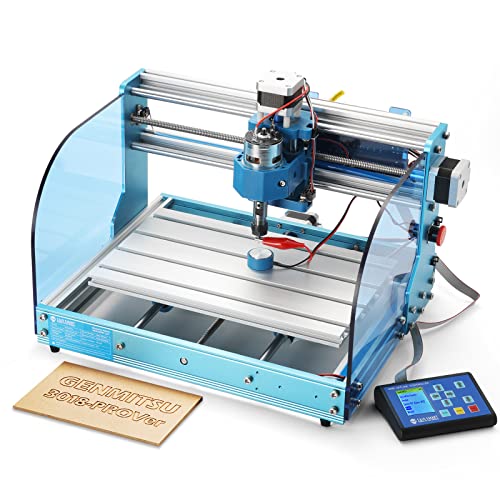

You can find a variety of small CNC routers for home installation on the internet. The SeinSmart Genmitsu CNC Router Machine 3018 is also competitive with its competitors due to its efficiency and affordability. The machine is excellent for a beginner. It has many features. SeinSmart 3018 comes with pre-assembled parts, so setting it up is very easy. All you need to do is set it up in 15 minutes. GRBL v1.1 experience is required to run this CNC router. System files for the Toshiba TB6S109 are silently installed. Opticouplers are also installed in the machine to protect the mainboard for its long life. Acrylic baffles on the sides protect you while watching the workpiece. By blocking dust from spreading everywhere, the baffles help keep the work area clean while the machine is in use. Aluminum is the only material used in the construction of this machine. Therefore, it is very stable, has a longer life span, and works well. Handheld remotes provide control of the machine’s X, Y, and Z axes. The 1.8″ display also displays information about your machine.SainSmart Genmitsu 3018 PROVer: Easy to Assemble and Use

Various models of CNC routers are available for smaller workshops and projects. The market is very competitive since new models are launched regularly from different brands. We provide you with a detailed buying guide so that you can select the right CNC router for your small shop. The market offers both advanced CNC routers and more user-friendly machines. CNC machines should be checked for their capabilities. A clear plan of the types of projects you want to complete is necessary to fully utilize your CNC router machine. Your project should be matched with the best option. Using a CNC router is needed when you want to print wood or other materials. Software should be in charge of the entire process. Software should be compatible with your computer if you plan on using it in your project. In order to determine the engraving area, it is important to measure it. In order to make small accessories, you should find the dimensions of small engraving tables. Due to the fact that these tables are flexible, experts recommend getting tables with a large surface area that can be engraved. Depending on the project and your budget, this can vary. A small shop needs to consider the drive system when choosing the best CNC router. There are three types of CNC router machines: ball screws, lead screws, and rack and pinions. Choose the one that meets your needs. Based on customer feedback, ball screws can handle a variety of materials. Motors contribute to both cutting speed and torque as well. Make sure your machine has a high-performance motor to provide fast cutting speed. Using the vacuum pressure, you can see how firmly the CNC machine holds onto the material. A strong vacuum system is capable of holding heavy materials. Last but not least, CNC routers are far from being expensive. Get a CNC machine at an affordable price that can meet your needs. It is ideal for workshops and DIY projects to have a small, inexpensive CNC router.Best Home CNC Routers: Buying Guide

Project Nature

Accessibility

Engraved Area

Transmission System

The Motor

Pressure In A Vacuum

Budget

Related Articles:

- Ortur Laser Master 2 Pro 20W Review 2024: In-Depth Guide

- 5 Best Laser Cutter Engravers 2024: Comprehensive Reviews

FAQs: Best Home CNC Machine Router

A CNC router: how to build one?

Home CNC routers are easy to build. To complete the task, you will need both materials and time.

Are our CNC routers easy to assemble?

Depending on your unit, you will have this decision to make. For example, bolts may need to be installed from time to time. The process may take an inexperienced user more than a day. If you don’t want to put together your own device, you can also buy pre-assembled CNC routers.

CNC routers are capable of what?

The CNC router can be used to cut, carve, and engrave steel, glass, plastic, wood, and foam. The bits and power of CNC routers determine which materials are compatible with them.

How much does a CNC router cost?

The cost of acquiring a CNC ranges between $189 and $8,000, depending on the model. Machines for industrial use are more expensive than those used for domestic use.

Conclusion

A wide variety of quality products are available, despite CNC routers’ modest size. Production accuracy and precision, as well as strong operational characteristics, are the main driving forces behind this.

Beginners are advised to learn and experiment with as many different machines as possible before purchasing their best router.